Frito Lay sets aggressive growth and productivity targets, so we can deliver industry best cost and service to our customers, and value for our shareholders. JMP Engineering's work delivering the Compact Palletiser program has exceeded expectations. We believe all the qualities that helped you (sound engineering, technical innovation, flexibility and responsiveness, fabrication and FATs, installation and field support, and competitive pricing) will enable JMP Engineering to continue to grow with Frito Lay

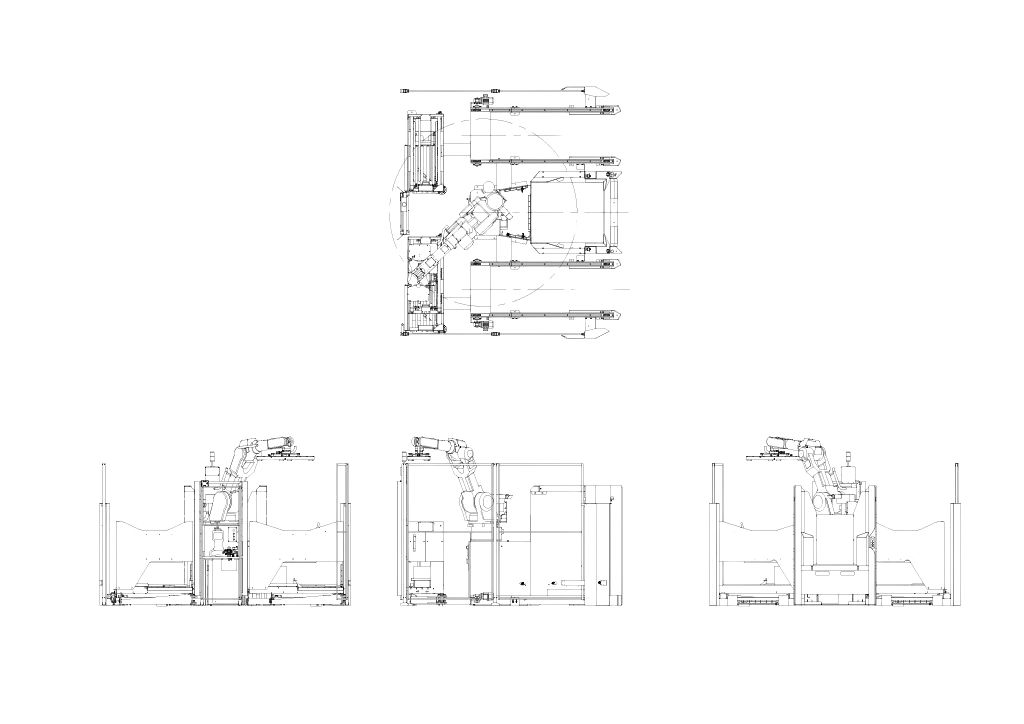

An ultra Compact Palletising Cell (CPC) with a modular design that can be installed in one day. A vertical case stacking system provides the required accumulation without robbing valuable floor space like conventional product conveyors. The robot controller, with its internal PLC, allows for simple operation without adding hardware cost.

The CPC program didn’t just solve one problem, it also inspired a new way to approach automation. The partnership continues to thrive as new innovations, collaborative designs and industry leading solutions are implemented across the Frito Lay/PepsiCo’s network of facilities.