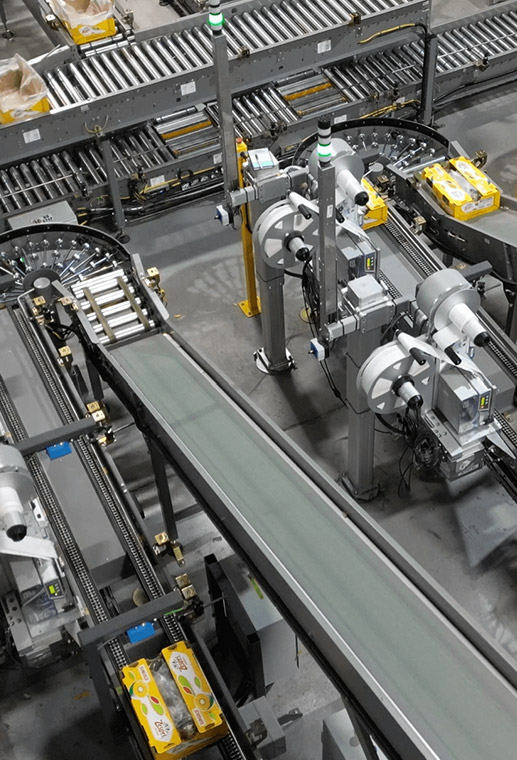

I wanted to pass along my sincere thanks for the work JMP Engineering has done for us over the years. Your equipment engineering, durability and field teams are all exceptional. It’s a testament to the quality of work and people in your organisation that keeps us coming back.

ProForm

General Manager - ProForm