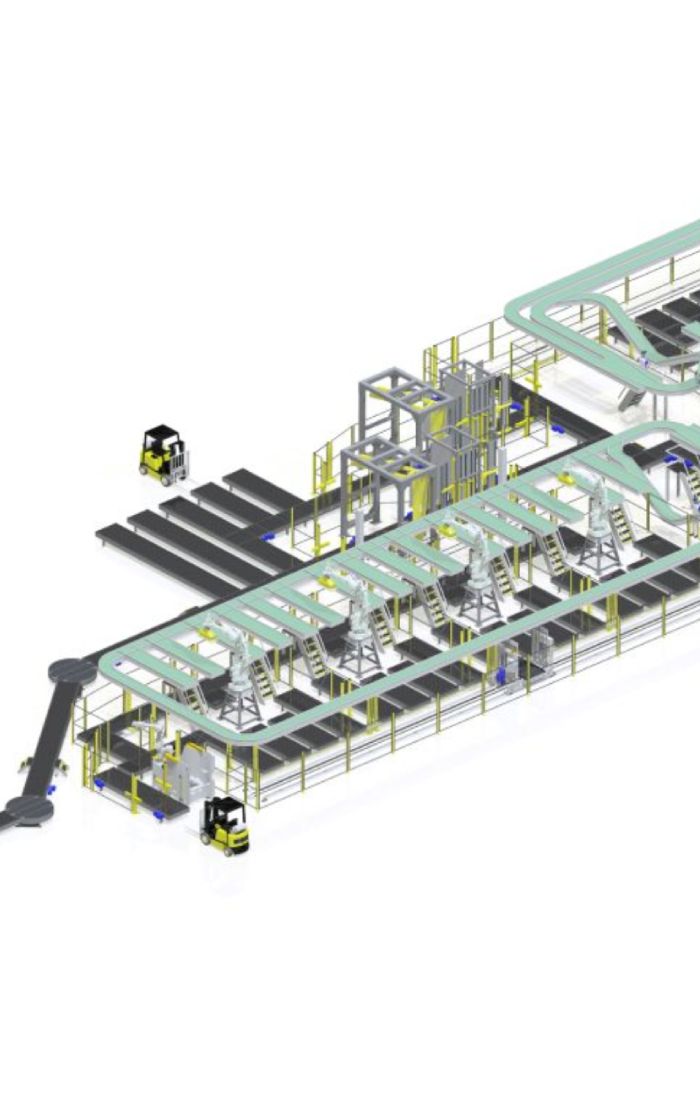

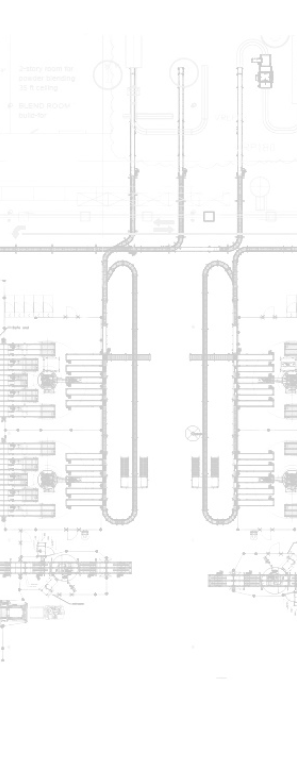

Consultation

No two solutions are ever the same – our broad range of experience means we can get to the heart of a challenge quickly. From the moment you get in touch, you’ll be working directly with our most experienced team of engineering experts.

We’ll get clear about the specific needs and challenges of your project, such as SKU size, weight, material, rate, site layout, traffic flow and traceability requirements. Experience has taught us the right questions to ask up front to get the detail that is essential to achieving a successful outcome.