Hiring and keeping employees that were required to handle and stack heavy bags and boxes, day in and day out, was a challenge for GHF. Automating this process was challenging due to the high-production rates and unique package sizes. In addition, some products had to be loaded into totes, which made it difficult to use typical end-of-arm tools in this confined space.

Hiring and keeping employees that were required to handle and stack heavy bags and boxes, day in and day out, was a challenge for GHF. Automating this process was challenging due to the high-production rates and unique package sizes. In addition, some products had to be loaded into totes, which made it difficult to use typical end-of-arm tools in this confined space.

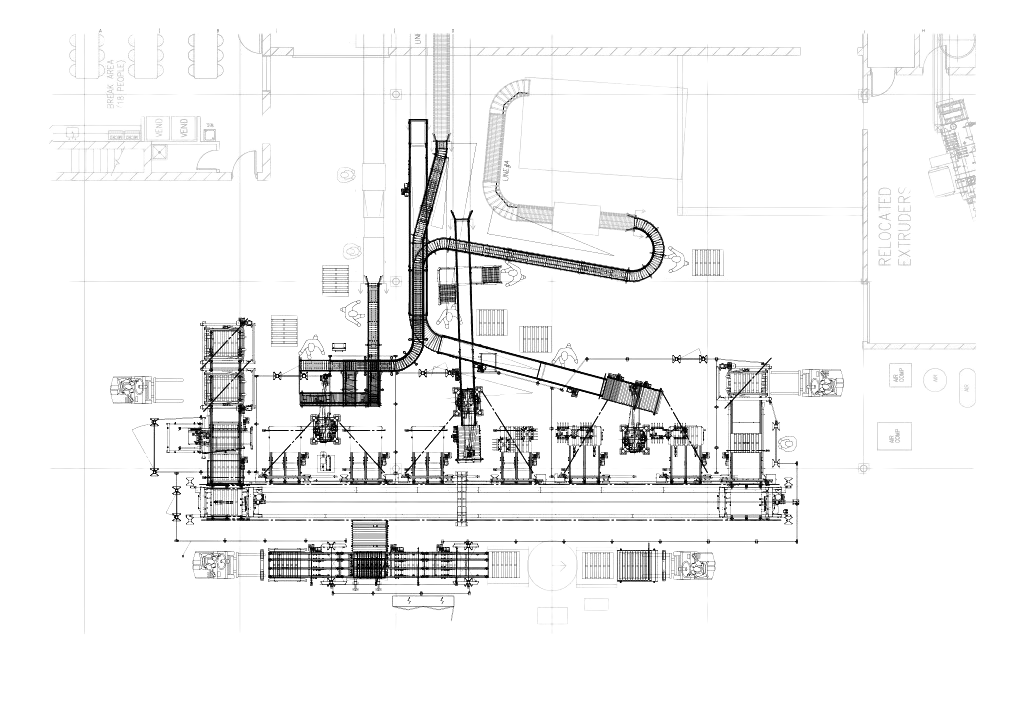

We created a custom system that worked around the site’s existing equipment and infrastructure, meaning that infeed and outfeed conveyors integrated seamlessly into the operation.

\

After the first successful installation, we were thrilled to partner on further projects across several site locations. With each project, we’ve gotten to understand the nuances of their business and their operation, each time carving out more opportunities for efficiency and performance.